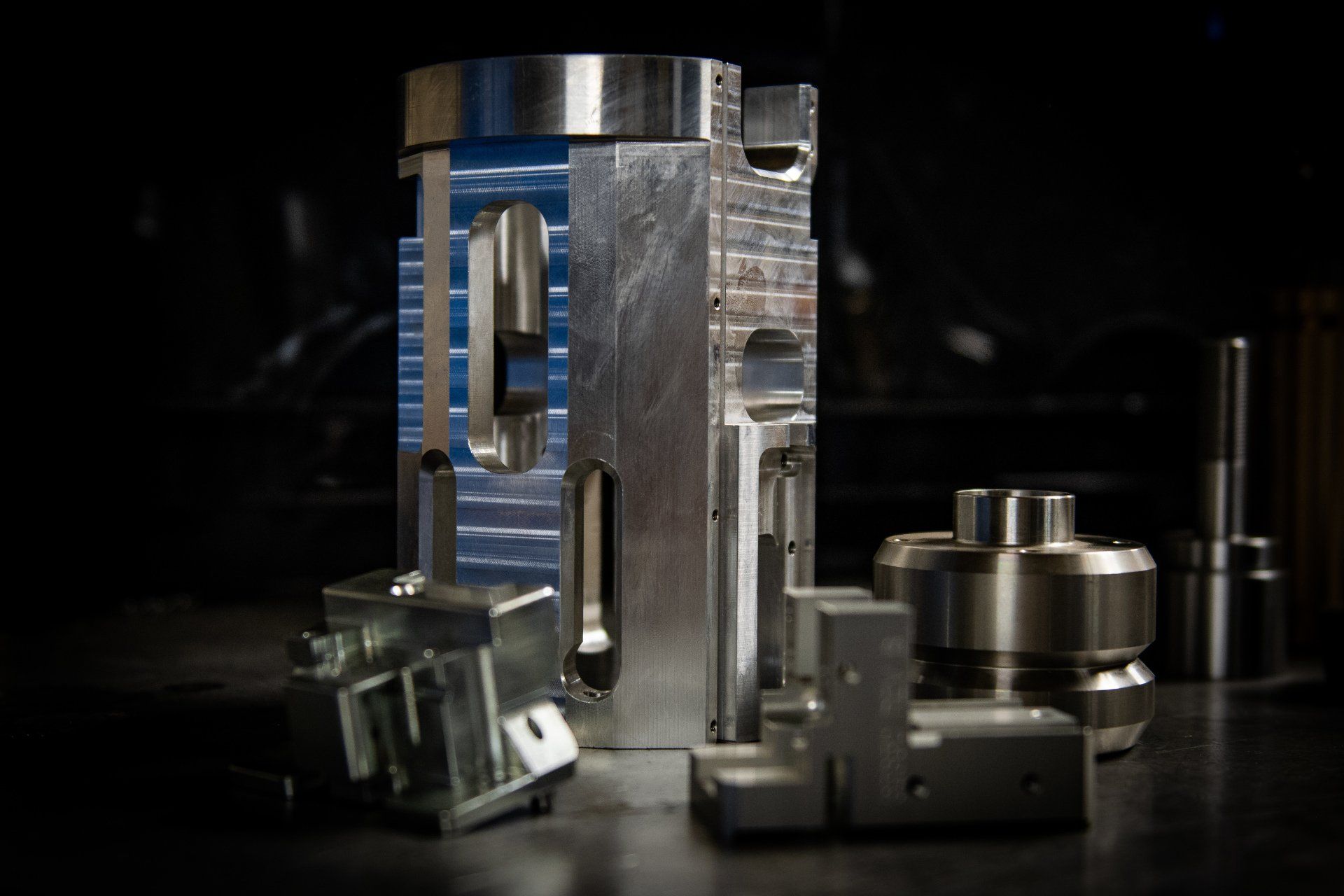

Quick Turn Precision Machining

Quick Turn Precision Machining is a full-service machine shop. With over 23 years of experience, we specialize in small to medium rapid turnaround precision machine work. From custom tooling and intricate molds to small specialized parts. We proudly serve companies Nationwide. Call the team at 801-334-6800 to start a project.

Milling

With state-of-the-art CNC milling machines we are able to tackle one-piece prototypes or long production runs. Using 3-D CAD/CAM systems, we have the ability to import solid models and generate CNC code directly.

- Mazak VCN 530C 20x40 travel with 4th axis

- Mazak VCS 510C 20x40 travel with 4th axis

- Mazak VCU 500C 20x40 travel

- Mazak VCU 400B 15x30 travel with 4th axis

- Mazak VCU 400B 15x30 travel

- Mazak VTC-300C 30x65 travel

- Mazak VCN Compact 17x20 travel

- Mazak VCN Compact 17x20 travel

- Fryer MB14 20x40 travel

- ProtoTRAK 20x40 travel (x2)

Turning

Our use of state-of-the-art CNC turning machines with milling operation saves time by eliminating costly setup time, and as with our milling, we can tackle one-piece prototypes or long production runs. And again, with our 3-D CAD/CAM systems and know-how, we can import your solids and generate CNC code directly.

- Mazak Quick Turn Nexus 200-ll MSY with Bar Feeder, Parts catcher, and Roto-Pack conveyor

- Mazak Quick Turn Nexus 250-ll MSY with Parts catcher

- Mazak Quick Turn Nexus 200-ll M with Parts catcher

- Mazak Integrex j-200

- Ezpath lll

- Ezpath

Water-Jet Cutting

Large scale precision machining: For larger parts or multiple parts from large stock up to 5' x 10' [1.5m x 3m].

The OMAX 60120 JetMachining Center cuts complex flat parts out of most materials including metal, plastic, glass, ceramics, stone and composites directly from a CAD drawing or DXF file. Extremely hard, reflective and nonconductive materials can also be cut.

No tool changes or complex fixturing dramatically reduces setup times and the smooth finish often eliminates the need for secondary machining. The Tilt-A-Jet lets the OMAX JetMachining Center achieve virtually zero taper with most materials. The Tilt-A-Jet can position the nozzle at an angle calculated by the software to exactly offset the taper from the abrasivejet. Taper doesn't disappear—it just gets moved to the scrap part of the material, leaving your part with exactly square edges.

We offer Waterjet cutting on Two of our 60 inch by 120 inch OMAX Tilt-a-jet Waterjets.

With the latest in Waterjet technology using a High Pressure stream of water (up to 60,000 psi) combined with an abrasive and the Tilt-a-Jet taper compensating head we are able to make a precision cut in a variety of materials including, but not limited to: Aluminum, Stainless, Tool Steel, Plastic, Rubber, Foam, Wood and even Hard Stone(Ceramic, Porcelain, and Granite)

Welding

Yes, you can get great welds from a machine shop, if you are using Quick Turn anyway.

- Miller Syncrowave 350LX Tig

- Miller Millermatic 350P Mig

Saws

- Hyd-Mech S-20 horizontal

- DoAll vertical

Inspection Equipment

- ZEISS ECLIPSE CMM

- OGP Optical Comparator

- Mitutoyo QM Height Gage 600

- Diverse micrometers, calipers, pin gauges

- Rockwell tester

- Inspection equipment Calibrated Annually and Tracked with GAGEpack Gage Calibration Management software

Heat Treating

Having our own heat treat furnace in-house allows us to control processes on parts from start to finish—and on time.

Cress double oven electric furnace 12x12x19

ASSEMBLY

Quick Turn has the capability to assemble small to large machined and fabricated parts in-house. This mechanical assembly service is partnered with our reliable purchasing management system, which provides you with assemblies and sub-assemblies. Our focus is to help reduce the overall part number count that you have to manage.

Supplier Recognition Letters

CONTACT INFORMATION

Address: 3340 S. 1500 W. Ogden, Utah 84401

Phone:

801-334-6800

Fax: 801-334-6799

Email: quotes@quickturnmach.com

Business Hours (Office & Shop):

Mon - Thur 7:00 am – 4:30 pm MST

Closed Every Friday